Projects

Building the

Future of Energy

TODAY

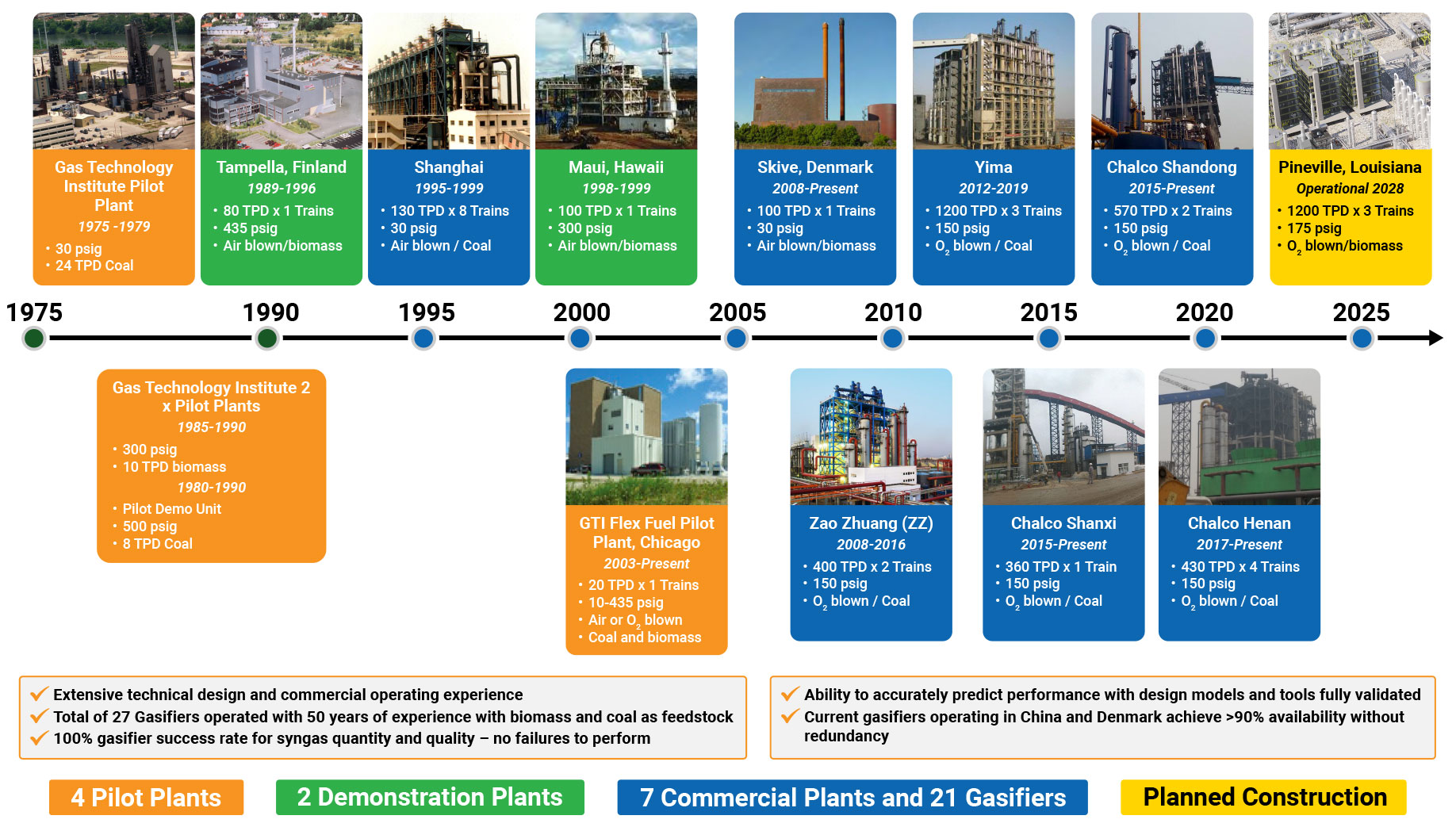

SunGas Renewables History of Expertise

SunGas Renewables gasification technology is backed by 50 years of expertise to deliver lower carbon intensity biofuels for a sustainable energy future.

Beaver Lake Biofuels

SunGas together with C2X is leading the production of advanced biofuels with the Beaver Lake Biofuels project, a pioneering initiative repurposing the former International Paper site in Rapides Parish, Louisiana. This $2 billion facility will create over 1,150 construction jobs and provide more than 100 permanent local positions, breathing new life into the sustainable forestry industry and local community.

By leveraging SunGas’ S1000™ standardized gasification technology, Beaver Lake will convert sustainably sourced and underutilized wood resources into approximately 500,000 metric tons of renewable methanol annually.

Beaver Lake is the first of multiple SunGas facilities planned across North America, backed by a strategic investment from C2X. As the shipping sector seeks low-carbon fuel alternatives, green methanol is gaining traction, with industry demand projected to reach 500 million tons per year by 2050 (IRENA). With proven expertise in gasification technology, SunGas Renewables is leading the future of clean advanced biofuels.

| Location | Pineville, Louisiana |

| Partners | C2X, Maersk, Louisiana Economic Development, Louisiana Central, Cleco, Didier Consultants, Kiewit |

| End Product | Green Methanol |

| Operating Fuel | Woody Biomass |

| Status | Construction of the new facility is planned to begin in Q3 2026, with operations beginning in 2028 |

S1000™

Standardized

System

Commercially Operational Skive Plant, Denmark

The gasification technology was commercially deployed utilizing biomass in Skive, Denmark in 2008 and the plant is still operational, providing 12 MWth of district heating and 6 MW of electric power using wood pellets as the fuel. The plant utilizes bubbling fluidized bed (BFB) technology, which forms the foundation of SunGas’ proprietary process. This gas is then catalytically reformed and used in IC engines in a combined heat and power (CHP) application. The heat is consumed in the local district heating network and the electricity is sold to the grid.

| Location | Skive, Denmark |

| Partner | Andritz-Carbona |

| End Product | District Heating and Electricity |

| Operating Fuel | Biomass |

| First Syngas Production | 2008 |

| Status | Operating |

Woody

Biomass

Tampella Power Inc.

In 1989, the gasification technology was licensed to Tampella Power Inc., who built a multifuel pressurized pilot plant in Tampere, Finland to further develop and demonstrate the technology for air blown IGCC power generation with biomass and coal. This fully integrated plant included all gasification island components from fuel preparation through waste heat recovery and hot gas cleanup. Gas generated in the plant was combusted in a heat recovery boiler producing district heat for the city of Tampere. The facility processed up to 42 tons/day of coal and 60 tons/day of biomass at pressures up to 435 psia. The plant logged 3,800 hours of operation with 5,900 tons of fuel processed in 26 test runs. The tested fuels include coal (Polish, Colombian, coke, German lignite) and biomass (wood, paper mill wood waste, forest residue, willow, straw, alfalfa) and mixtures of coal and biomass. At the end of demonstration tests the plant was decommissioned and is no longer operated.

| Location | Tampere, Finland |

| Partners | Tampella Power Inc. |

| End Product | Electricity |

| Operating Fuel | Biomass & Coal |

| First Syngas Production | 1989 |

| Status | Retired |

Biomass

and

Coal